Wietech3D specializes in providing solutions for 3D printing, additive manufacturing, and traditional manufacturing. Our services cater to a wide range of industries, including the medical sector, automotive, aerospace, industrial manufacturing, and consumer goods. We collaborate with leading companies in various sectors.

Our comprehensive range of services covers everything from assisting in design and material selection to prototyping and full-scale production. We take pride in delivering customized solutions that meet your specific requirements and budget constraints.

Our approach involves personalized attention and a quick and transparent quotation process. We offer expert advice to ensure feasibility and scalability, fostering collaborative relationships focused on innovation. Moreover, our Extensive Knowledge Base serves as a valuable resource to provide you with the necessary information and empower your decisions.

FDM (Fused Deposition Modeling) or FFF (Fused Filament Fabrication) is an additive manufacturing process where a thermoplastic filament is heated to its melting point and then extruded through a nozzle onto a build platform, layer by layer, to create a three-dimensional object. This process is widely used in desktop 3D printers and industrial additive manufacturing systems.

SLS (Selective Laser Sintering): SLS is an additive manufacturing process that uses a high-powered laser to selectively fuse powdered material, typically nylon or other polymers, into a solid structure, layer by layer.

SLA (Stereolithography): SLA is a 3D printing process that uses a UV laser to cure liquid resin into hardened plastic layer by layer, building up a 3D object from the bottom up.

MJF (Multi Jet Fusion): MJF is an additive manufacturing process developed by HP that uses agents, heating elements, and fusing agents applied in layers to build up a 3D object. It involves fusing together a powdered material with a binding agent using thermal energy.

DLP (Digital Light Process or Printing): DLP is a 3D printing technology similar to SLA but uses a digital light projector to cure liquid resin into hardened plastic layer by layer, instead of a laser.

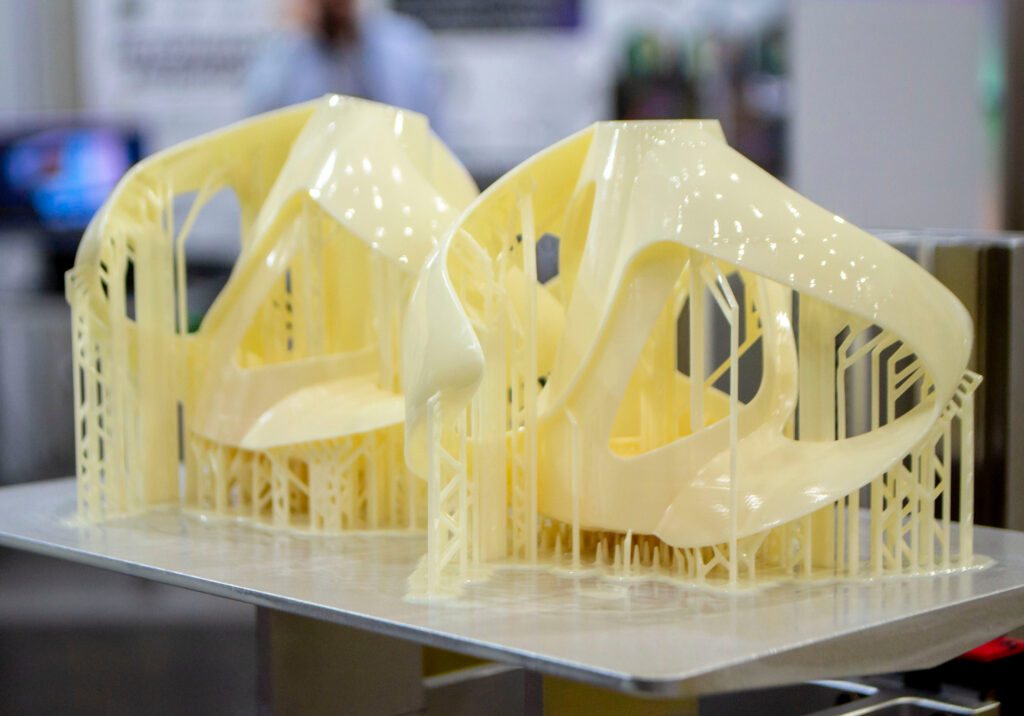

MJP (MultiJet Printing): MJP is a type of 3D printing technology that utilizes inkjet printing principles. In MJP, droplets of material are selectively deposited onto a build platform in layers. These droplets solidify or cure upon exposure to UV light, creating the desired 3D object. MJP is known for its high resolution and accuracy, making it suitable for creating detailed parts with intricate geometries. It’s often used in various industries including aerospace, automotive, and healthcare for prototyping, product development, and manufacturing.

Supply Chain – Planning a capital expenditure involves commencing with the development of a return on investment (ROI) analysis and collaborating with Wietech 3D to capitalize on our additive manufacturing proficiency and parts services.

Prototyping – Multiple design iterations, validate fit & function, concept models, reducing your design cycle and time to market.

Manufacturing – Enhance the productivity and optimize your supply chain efficiency with Wietech’s 3D part services, reducing the expenses associated with your bridge or low-level production.

Tooling – Building complex intricate geometries/tools, jigs, fixtures, molds and molds inserts reducing your lead times, warehouse inventory and space increasing cost reduction.

Wietech 3D partnership – Our approach is consultative, integrating advanced technology with outstanding customer service and expertise leveraging the full potential of additive manufacturing and tailor solutions to your needs.